LIVAKKA TOWABLE DISC INJECTOR

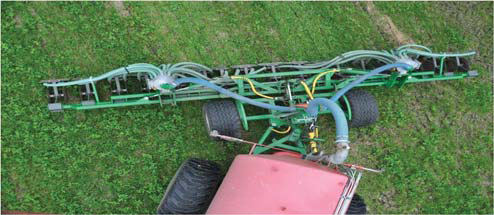

Working width 8m

The construction of the disc injector also allows for mounting with lighter-duty slurry tankers, because the disc injector does not require a separate hitch arm to operate the machine or a separate frame for coupling it. The disc injector is also easily retrofi tted. The durability of the disc injector is outstanding because it is never subjected to the weight of the slurry tanker.

The towable construction of the disc injector reduces its point load on the ground. Despite its towable construction, the disc injector-trailer combination can be backed up normally, as the disc injector has forced steering.

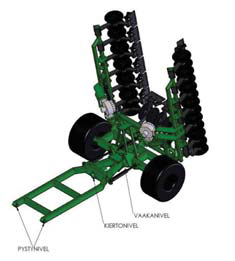

The drawbar articulation offers excellent clearance for the disc injector to follow the contours of the terrain and pressure accumulators dampen its movements, acting as a sort of overload protection. Built as low to the ground as possible, the disc injector is also stable when running on sloping terrain.

• The disc injector has its own axle assembly

– does not add to the slurry tanker’s axle mass.

• The disc injector is articulated to move laterally, horizontally and torsionally, which allows it to follow the contours of the terrain independently of the slurry tanker.

• In the single disc system, the slurry is injected to a depth of up to 10 cm – there is no need for high tractive power

• The disc diameter of 455 mm ensures that the discs will turn easily even in the most demanding conditions, without pulling stones to the surface

• Operates reliably on turf, stubble and tilled soil

• The slurry is injected into the furrow opened by the discs through a rubber injection cone

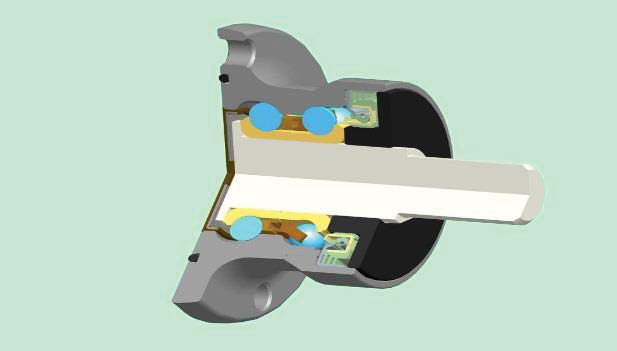

• The SKF bearings used in the discs are extremely well-sealed and reliable

• The disc suspension is equipped with the same durable elastomer suspension used on rotary tillers, can withstand heavy use and is very reliable

• The levelling plates mounted behind the discs fl atten any mounds or other irregularities in the soil surface (such as molehills) while injecting.

• These level the surface while working on ploughed areas

• Slurry is more effectively absorbed into tilled soil – the effect is accelerated and less nitrogen is lost to evaporation

• The towable disc injector has two Harsø distributors and 50 mm hoses, which ensure a superior slurry fl ow capacity

• Hoses are kept as short as possible without any unnecessary connections – the risk of clogging is nearly nonexistent and hoses can be quickly discharged

• If necessary, it is possible to operate at half the working width

| LHDD6 | LHDD8 | Towable disc | |

|---|---|---|---|

| 4-point hitch arm-mounted CAT III | 4-point hitch arm-mounted CAT III | Own frame | |

| Working width cm | 600 | 800 | 800 |

| Coulter type | 2-disc | 2-disc | 1-disc |

| Coulter diameter cm | 40,5 | 40,5 | 45,5 |

| Number of coulters | 23 | 29 | 16 double disc packages |

| Disc spacing cm | 27 | 27 | 25,8 |

| Suspension type | Hydraulic | Hydraulic | Rubber element |

| Transport width mm | 3000 | 3000 | 2990 |

| Distributor | 1 x Harsø | 1 x Harsø | 2 x Harsø |

| Slurry hose diameter mm | 50 | 50 | 50 |

| Oil requirement max l / min | 40 | 40 | 40 |